The size and dimensions of the toast can be customized. The production line can also be connected to a plate setting machine and a drag box, and can produce two production lines in one.

Cut breads

After pressing the sheet, shape the dough into rows by rotating the knife or guillotine. The result is a wide variety of breads, including: Ciabatta, triangle, square, hexagonal, cut baguettes, cut pain and Balarustica, flat bread, pita and pizza.

Rolled breads

After pressing, cut the dough with a guillotine. Next, the dough is rolled and molded using Seny’s molding techniques. Baguette rolls, rolls and balarusticas, free-standing bread, canned bread, toast (open and closed tops, 4 slices), brioche and bread rolls are all results of this method.

Rounded breads

After the sheet is pressed, the dough is cut and rounded using the SENY rolling device to make traditional breads such as buns, rolls, sandwich rolls and hamburger buns.

Tin breads

The cut and rolled dough pieces can be placed in the baking tin. The final products of this process include tin bread and toast bread (open bread, closed top bread, 4 slices and multiple slices) as well as the typical English sandwich bread.

Versatility is the key to our bread range. Thanks to its modular setup, this flexible line allows you to produce a variety of breads by replacing only one or more modules. A good recipe is the key to the quality of bread. As we seek to produce a wide range of high quality breads, the bread line is able to handle a wide range of formulations, including breads with high water content (strong hydration) or low salt content, containing biological ingredients, gluten-free, pre-fermented, Levain, parent dough, biga and sponge dough. All of these recipes have resulted in a very wide range of bread products. If you want to produce tin bread in a bakery, we focus on achieving a fine and consistent crumb structure, just like highly absorbent artisanal bread, we focus on achieving a light, true and open bread structure.

Baking system

Seny develops and supplies industrial baking equipment, systems and solutions for the food processing industry. We have been in the bakery industry for more than 17 years and as a result have accumulated extensive knowledge about food and its production techniques.

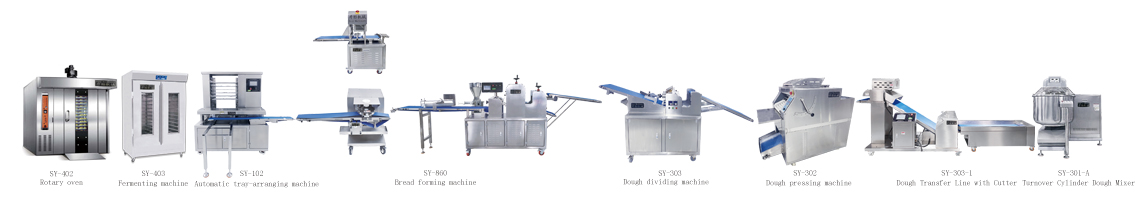

Industrial baking equipment and systems

We are a global supplier of food processing equipment and (custom) industrial baking systems. Our production lines and turnkey solutions guarantee efficient machine performance. Combined with easy conversion and maintenance, the lowest possible cost of ownership can be achieved. We are driven by global market forces and have therefore developed into a company with an international outlook. Production lines, baking systems and turnkey solutions for every continent are an important part of our business today. Seny is headquartered in Shanghai.

We can provide you with meaningful advice

We offer you the highest quality industrial baking equipment and systems, manufactured according to your wishes and requirements. Find out how we use our experience and passion to work for you. Our solutions will allow you to face the future with confidence. Welcome to Seny!

Q:Are you trading company or manufacturer?

A:We are a factory and specialize in manufacturing food machine over 14 years.

Q:What information should let you know if i want to get a quotation?

A:The product you want to produce

The size of the product

If it is possible,please also provide with pictures or video for checking.

Q:How long is your delivery time?

A:One week after paymaent.

Q:What about the after-sale service?

A:Grantee period is 13 months,we also provide life-long paid repair or arrange engineers to do service for you.

Q:Where is your factory located?How can i visit there?

A:Our factory is located in Shanghai City,You can fly to Pudong or Hongqiao airport directly.I will pick you up.All our clients,from home or abroad,are warmly welcome to visit us!

Q:How does your factory do regarding quality control?

A:Quality is priority.We always attach great importance to quality control from the very beginning to the end of the production.Every product will be fully assembled and carefully tested before it’s packed for shipment.Our machine also has passed the CE,SGS,TUV certification.

Q:Do you make customized machine?

A:Yes,we can provide customized machin.We also provide turnkey solution at any time.

Q:Can you arrange factory inspection and machine checking before order?

A:Yes,we arrange fatory inspection and machine checking.

Q:How many employee is needed for the machine?

A:Depends on customer’s machine condition for single machine ,need 1 employee,for production line depands on the situation.

Q:Where can we buy the machine’s parts?

A:Our company can provide machines for you any time.